It is a legal requirement for any stored heated water to be kept at a minimum of 60ᵒC to prevent the growth of bacteria such as Legionella. However, storing water at this temperature poses scalding risks to users should the water temperature not be reduced before reaching facets and shower heads.

For example, it takes as little as one second for a full thickness burn from contact with water at 68ᵒC while if the temperature was reduced to 50ᵒC it takes 5 minutes. This risk can be minimised by installing tempering valves in your home.

The recommended bathing temperature is 37-38ᵒC, this should also be considered as a maximum temperature for young children.

As part of your Venatic inspection, your inspector will measure the temperature from the outlets in the bathroom areas of the home and report on any temperatures over 50ᵒC with a recommendation to seek further advice from an appropriately qualified plumbing contractor. While your system may have been installed in line with regulations at the time of installation and remains compliance, it is worth considering improvements to increase the safety of your home.

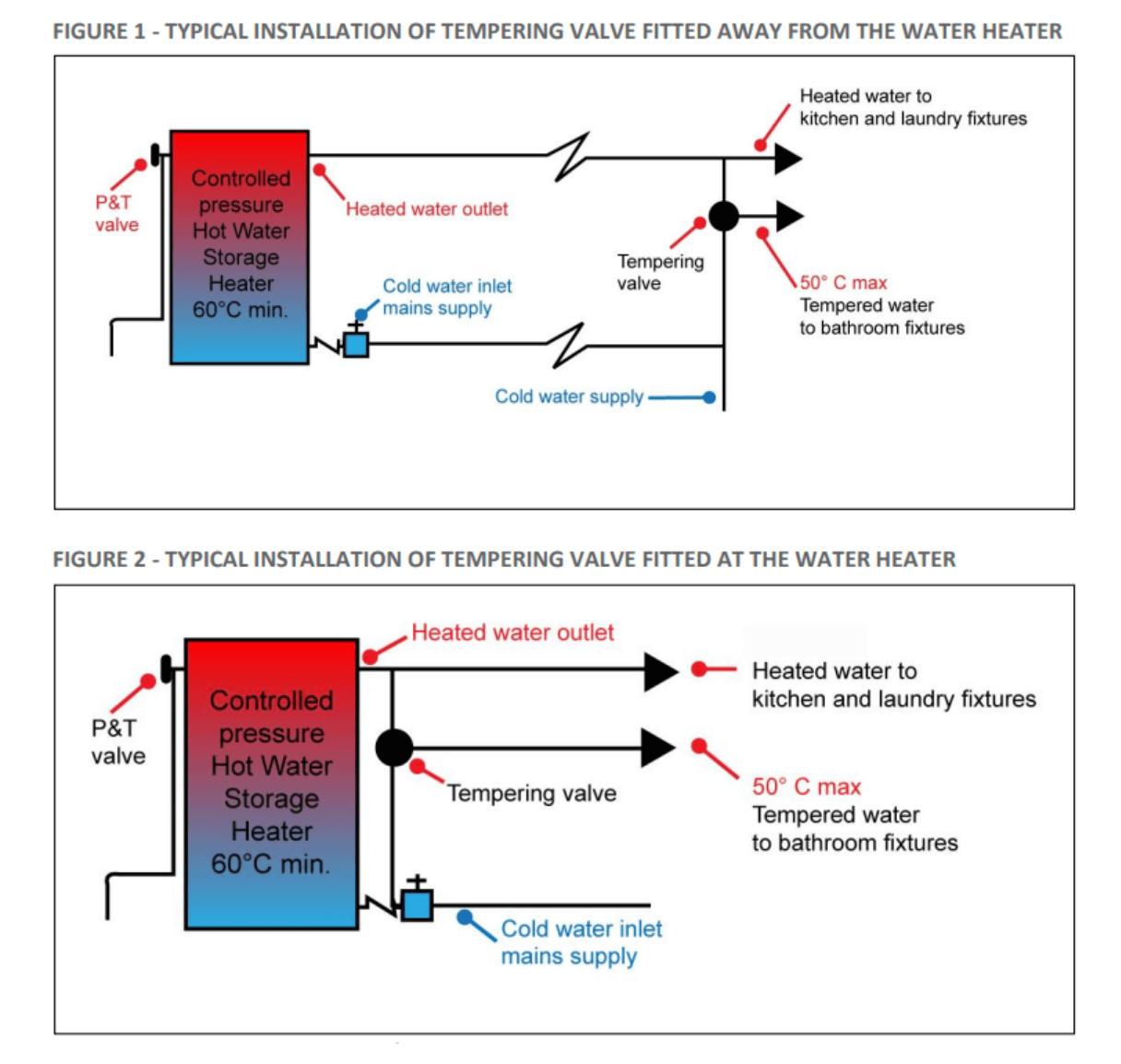

Water supplied to kitchen and laundries is not required to be reduced as appliances such as dishwashers and washing machines may require hotter temperatures to operate efficiently.

The Regulations

The Plumbing Code of Australia sets standards that aim to protect residents from illness caused by bacteria such as Legionella while also significantly reducing the risk of scalding.

As mentioned above, all stored heated water must be stored at above 60ᵒC to prevent the growth of bacteria.

Tempering valves are now required for all new builds, bathroom and ensuite renovations to reduce the delivery temperature to a maximum of 50ᵒC for personal hygiene purposes (typically in bathroom areas). It is not a requirement for tempering valves to be installed during replacement of a hot water service or replacement of parts of a hot water service.

For early childhood centres, schools, nursing homes and similar facilities for young, aged, sick or disabled persons the delivery temperature for personal hygiene purposes must not exceed 45ᵒC and be controlled by a thermostatic mixing valve.

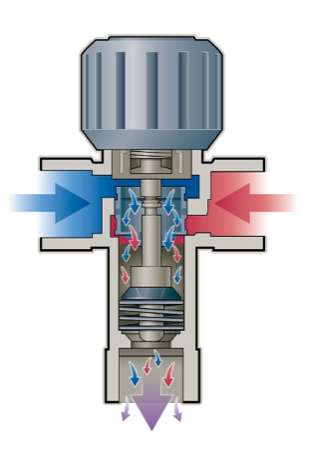

Tempering Valves and Thermostatic Mixing Valves

Tempering Valves are typically found in the home as a means of reducing the temperature of stored water.

Thermostatic Mixing Valves are similar in design and can be found in residential settings however, they are more typically found in commercial environments as they are more accurate (within 1ᵒC) and respond more quickly to variations in temperature and pressure.

These valves can be installed at the water heater itself or can be installed further downstream to reduce the water temperature in specific areas of the home.

Instant/Continuous Flow Hot Water Heaters

As instant hot water heaters do not store heated water, there is no requirement to heat the water above 60 .

Water heaters complying with AS 3498 are designed with a maximum temperature of 50 C and do not require further tempering. It is worth noting that if the entire home is supplied for this unit, the kitchen and laundry temperature of 50 C may not be appropriate for the appliances in the home.

Continuous flow water heaters with electronic temperature control are typically supplied with a set default maximum delivery temperature of 55 C or 60 C, if this default setting cannot be reduced to 50 C, installation of a Tempering Valve may be necessary. Alternatively, if the unit is supplied with a set default maximum delivery temperature of C, it must be marked as such by the manufacturer.